Background

Multi Calor Pipes

In the last ten years, Aquatechnik in Sydney has been supporting the development of multilayer piping technology, to allow the introduction of the “safety system”.

The technology improvement has run over all the production phases, starting from the application of new adhesives that are more resistant to mechanical stresses, aluminium alloy plates with higher performances which are easier to weld, up to the synchronization of the entire process to assure maximum quality standards.

This new philosophy took the multi-calor composite pipes to the top of the world classification, also thanks to the good balance between cost and quality.

The multi-calor pipes are classified according to UNI EN 21003, class 1; thanks to its high performances, multi-calor is the only pipe that can be used with the complete range of Aquatechnik fittings:

■ safety system (in PPS – polyphenylene sulfide) Available now, in Australia!

■ crimp-fitting (in galvanized brass and stainless steel)

■ valu-technik (hydronic heating-cooling radiant panel system, low temperatures)

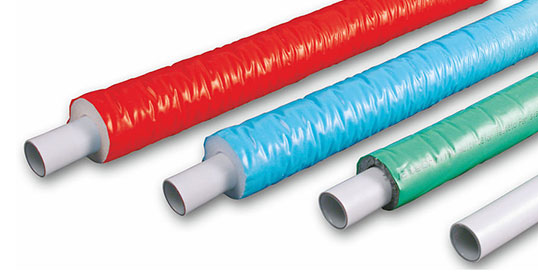

The multi-calor pipes are also available in pre-insulated rolls.

Advantages

- Lead-Free;

- Leak-Proof;

- Corrosion proof;

- Sizes from 16 up to 90mm allowing for substitution of copper above 25mm;

- Cost comparison: compared to copper it shows a 35% reduction in material costs;

- Less processing time: the system helps to reduce labour costs by at least 60% due to its fast joint process, especially for large sizes (e.g., jointing a 75mm pipe and fitting only takes 55 seconds);

- When used for swapping from copper pipes, associated costs such as fire watchers, hot work permits, hot work operators, extra workers, and consumables, will be cut, resulting in an extra saving benefit;

- Great resistance to high working temperatures and pressures (max. working temperature from –45C° to +95C° up to 1000 kPa);

- Chemical stability and safety of potable fluids for human consumption;

- Suitable for use in over-chlorinated commercial hot water services and high resistance to chlorine super shock treatments (hospitals/ aged care facilities);

- Reliability and long-time life of piping installations/plants (long-time life 50 years, 25 years warranty);

- Fluid flow-ability and lower pressure drops;

- Lower thermal leakage;

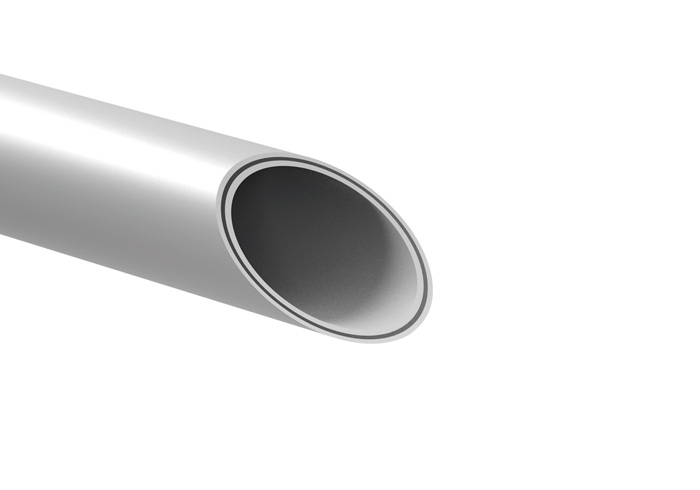

- Increased aluminium thickness: compared to other composite pipes, Aquatechnik’s multi-calor pipes have a 30% minimum increased thickness over competitors. The aluminium layer adds strength and rigidity to the pipe, making it more resistant to bending and deformation. This allows the pipe to behave similarly to metallic pipes in terms of elongation and structural integrity;

- Impermeable to oxygenated fluids;

- Energy efficient;

- Zero wastage: guaranteed money-saving system;

- Pre-insulated pipe coils for hot/cold/chilled water available from 16 up to 32mm;

The multi-calor pipe comprises of an inner layer of Pex-B, and can be used for all hydro-sanitary, heating, conditioning systems and for installations with radiant panels and several applications more, allowing material saving.

Utilisation Fields

The multi-calor pipes are mainly used in the following fields:

House Building:

■ conveyance networks, sanitation, heating, cooling and conditioning

systems, garden irrigation

Industrial:

■ conveyance networks and sanitation, heating and cooling systems,

compressed-air networks, power to hydraulic circuits of machine tools

Services Sector:

■ shops, laboratories, medical studies, schools, gyms, restaurants,

public utilities, greenhouses, farms and so on.

Working Conditions

The multi-calor pipe has a max temperature of 95° C at 10 bar pressure (1,000 kPa), and minimum temperatures (less than 0° C), through the use of a special antifreeze (in HVAC applications), preventing icing inside of the pipes.

Time and money saving installation: thanks to their excellent mechanical characteristics, the Aquatechnik multilayer pipes can be bent, instead of employing fittings thus obtaining significant advantages from an economical point of view. Compared to metallic pipes, Aquatechnik multilayer pipes have a greater resistance to chemical compounds, and may undergo treatments (eg. super chlorination shock) for several years without being damaged.

Excellent flexibility: the combination of cross-linked polyethylene and aluminium, guarantees excellent flexibility when bending (also when bent manually) and dimensional stability in the long term.

Reduced pressure loss: the extremely smooth internal surface, as well as preventing the formation of deposits such as lime scale, ensures reduced pressure loss also with the passage of time.

Guaranteed durability of at least 50 years: the system has guaranteed the durability of at least 50 years in compliance with product standards; in this period the product can be used at pressures of 10 bar and temperatures as high as 95°C.

Barrier against oxygen and light: the butt-welded aluminium layer acts as a total barrier against oxygen and light, which in single layer plastic pipes would otherwise favour algae growth and the corrosion of the metal parts that make up the system.

Lower thermal expansion: thermal expansion is approximately 8 times lower than all plastic pipes and is similar to the expansion in metallic pipes (It means that they could easily replace copper due to the high performance, stability and very low elongations).

Non-toxic materials: the system is made up of materials that are completely non-toxic and is certified for the transport of consumable fluids and drinking water.

Light in weight: the pipes are extremely light in weight when compared with metallic pipes: weight is 1/3 of a similar copper pipe and is 1/10 of a similar steel pipe.

Environmentally friendly, the Green choice: The multi-calor pipe is produced with materials that can be completely recycled, which, at the end of their service life can be recovered. The production processes used are energy efficient and are of a low environmental impact; in terms of the environment and conservation of resources, the multi-calor pipe is in line with Green Building principles.

Production process for multi-calor pipes (multi-layer pipe PE-X/Al/PE-X)

ONE BRAND, SIMPLE SOLUTION

Aquatechnik Australia offer you different products for all solutions you need for piping systems.