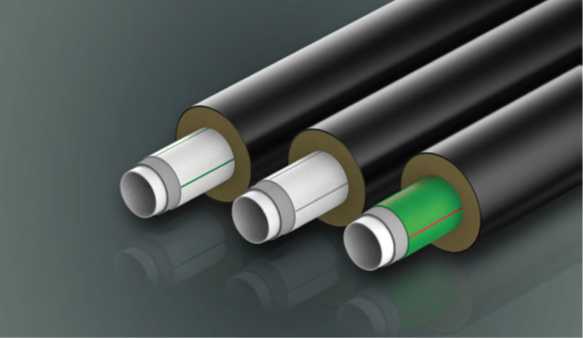

Pur Pre-insulated Pipe Systems

ISO-technik

Pre-insulated pipe system.

Main features

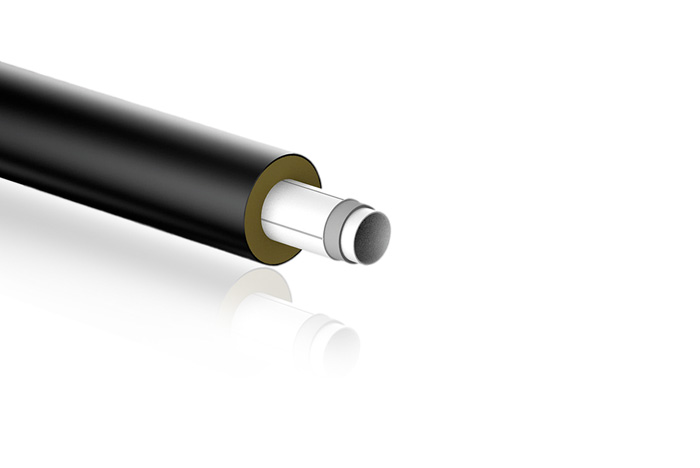

Pre-insulated pipe in PUR (stiff polyurethanic foam) protected by a HD-PE rigid casing sheath hose, made with Faser FIBER-T or FIBER-COND service pipes in PP-RCT WOR (White Oxidation Resistance) with high resistance against high temperatures and oxidation process.

The range of iso-technik products includes pipes and fittings with diameters ranging from O 32 up to O 315 mm, which are available in the following versions:

- Iso FIBER-T SDR 7,4, for sanitary systems at high temperature

- Iso FIBER-COND SDR 11, for sanitary systems at medium temperature and heating systems at high temperature;

- Iso FIBER-COND SDR 17,6 for sanitary systems at low temperature and heating systems at medium temperature and pressure;

The internal service pipes and fittings, which form the iso-technik system, are made using the most advanced materials, exclusively of European production: PP-R 80 Super and PP-RCT WOR (White Oxidation Resistance), developed by Aquatechnik with special blends of additives, which ensure greater resistance to the action of oxidants and ions of metallic origin. Their action also ensures high stability at high temperatures; the intermediate layer of the pipes, made of fibre reinforced polypropylene (PP-RF), reduces linear thermal expansion up to 70% compared to single-layer PP-R pipes. In addition, the “bonded” type system binds the high-quality polyurethane PUR heat insulator to obtain a compact system between the PE-HD (corona treatment) casing pipe and service pipes. These characteristics make the iso-technik system ideal for the remote transfer of energy between thermal power stations for the production of heat, chillers, heat pumps, geothermal systems, thermal-bath systems, etc. and the utilities involving networks of pre-insulated underground pipes, ensuring maximum safety and design/application reliability.

Application fields

Especially suitable for: air conditioning and compressed air systems, cold and hot water for mechanical installations at high temperature, such as chilled water industrial grade air-conditioning and HVAC systems, irrigation, shipbuilding, Geothermal plants, agriculture, UV exposure.

Advantages

The iso-technik system also has several advantages in terms of installation:

- Easy installation, quick application and safe joints by means of hot-melt sealing, from O 32 to 125 mm, butt welding from O 160 to 315 mm and electro welding.

- Dedicated welding equipment, with welding machines that mechanically self-align the pipes (from O 50 to 315 mm).

- Reduced linear mass with respect to metal pipes, so it is easier to manoeuvre the materials on site. It is not necessary to perform transverse welding trenches. No crane hoists and/or similar devices are needed to handle the items during the welding operation.

- Selection of single and/or double seal repairing joints to be carried out by means of on-site foaming using a PUR (two component) system.

- Facilitated pipe casing removal (service pipe cutting, removal of the heat insulator and casing), for customised installation.

- Possibility to assemble the line outside the trench and re-position in the trench at a later stage; it is very useful in the event of very bad weather conditions that make the trench unusable.

- In case there are no direction changes by means of “cold” installation, the iso-technik system offers excellent self-compensation features (only in case of underground installations). Therefore, it is not necessary to provide for loops, omegas, mechanical compensators, thrust bearings and all the solutions that increase work costs.

- Possible installation in “pre-tension” conditions with open trench, which consists in preheating the lines with temperatures that reach at least 50% of the max. design temperature, before being buried to close the excavation. This is possible also thanks to the reduced mechanical stresses that the pipe develops due to thermal expansion. These are proportional to E modulus, which for fibre-reinforced PP is about 1,5 GPa, 100 times lower than steel.

Energy saving system

- Minimum heat loss thanks to the low thermal transmittance U (W/m2°K) values, also in the presence of high heat gradients (ΔT). This factor is mainly characterised by the very low thermal conductivity l of the service pipe (0,19 W/mK, against 52 W/mk for steel). Together with an excellent and uniform insulation by means of rigid polyurethane foam (PUR) injected into the interspace between the service pipe and the external casing pipe (made with PE-HD), it makes the pipes highly efficient from the energy saving point of view.

- Energy saving thanks to its low thermal conductivity value. The iso-technik system is considered “energy saving”.

- Reduced pressure drops: the inner surface of the service pipes, with a roughness value of 0,007 mm (against 0,020 mm of steel pipes) generates low

- friction inside the pipes, promoting fluid flow and significantly reducing distributed pressure drops. This factor is reflected, for example, in considerable energy savings when using pumps: due to their design capacity, they can operate more slowly, decreasing the flow rate of the convoyed fluid and therefore consuming less energy, while still ensuring the required flow rate. In addition, this feature significantly reduces the noise of the plant.

- Increased system cleanliness: the polymeric material used for the production of the service pipes of the iso-technik range prevents the formation of sludge and

- the presence of rust, as well as drastically reducing limestone deposits. This prevents poor equipment performance, possible clogging problems in exchangers, filters, shut-off valves and other devices that are part of the system, resulting in reduced operation and maintenance.

- Excellent chemical resistance: the iso-technik system does not require anti-corrosion film-forming treatments, it is compatible with antifreeze products (MEG, DEG, MPG and PPG) and is resistant to many chemicals.

- No corrosive phenomena such as:

- galvanic corrosion due to metal couplings between different metal alloys;

- stray currents: it is not necessary to provide any cathodic-anodic protection since the fibre-reinforced PP-R pipe features high “electrical volume resistivity” of approximately 1014Ω;

- electrochemical or chemical corrosion due to the effect of water or chemicals dissolved in it.

Designing with the ISO-technik system

The specific solutions and the range of diameters also optimise the design work. The iso-technik system can be used to install distribution networks for hot or cold drinking water, reuse water distribution networks, heating/air conditioning networks and technological plants. The design with the iso-technik system offers the following advantages:

- Simplification in the calculation process and application of the products in the projects;

- Contribution to reducing the dispersion of heat from the distribution networks (thermal conductivity of service pipe l 0,19 W/mK);

- Reduction of electrical consumption of the circulating pumps, thanks to the low friction coefficient;

- Extended service life, over 50 years, by following the brochure guidelines;

- Eco-sustainability: 100% recyclable;

The choice of the most suitable system will be guided by the specificity of the plant to be installed, depending on whether it requires lines for drinking water or mechanical installations (air conditioning, compressed and industrial air in general). In the latter case, it is necessary to verify the chemical compatibility with the fluid supplied.