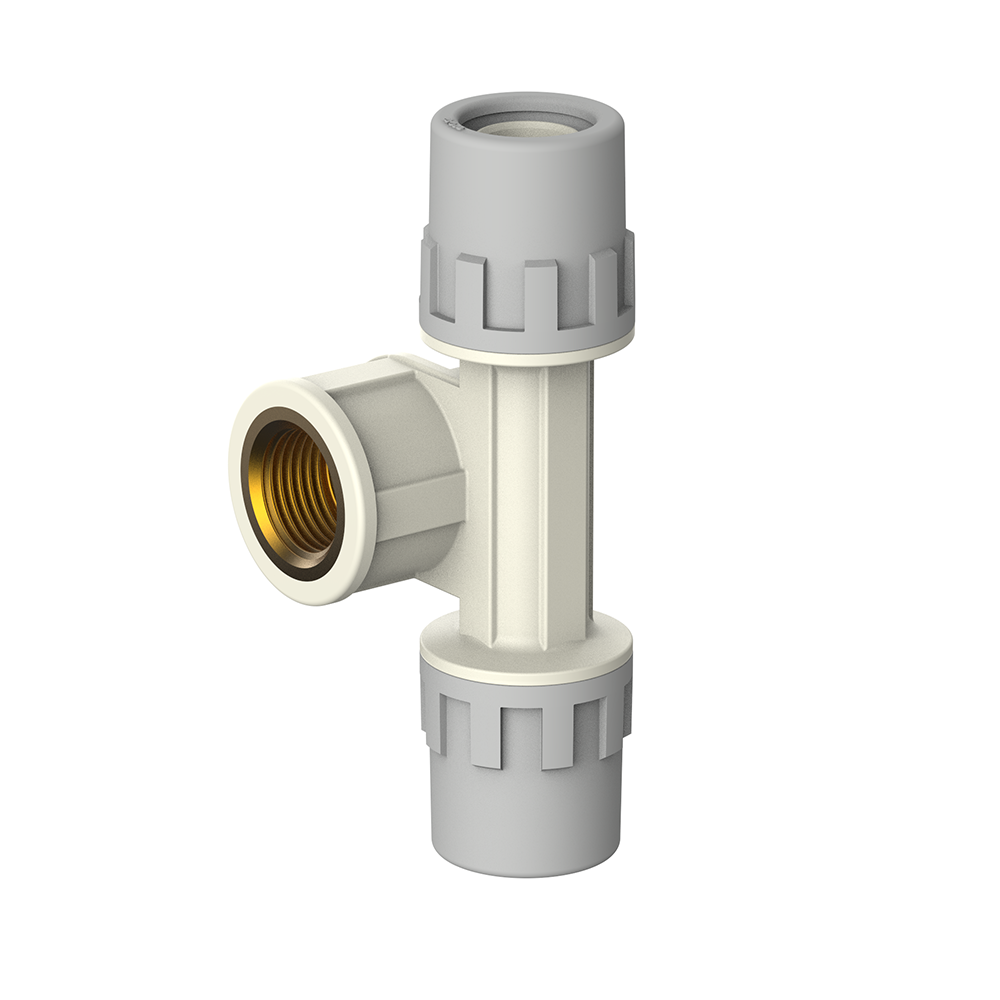

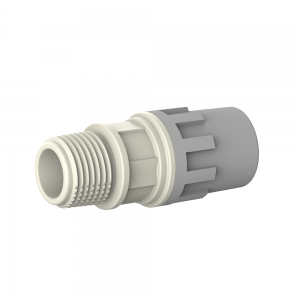

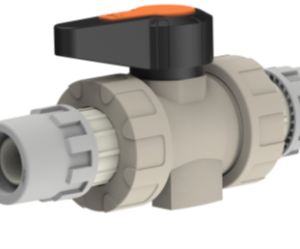

The lead-free polymer safety fittings are the result of continuous technical innovation and research. This new range was designed and patented to reach the highest safety standards regarding the connection of in-wall multi-layer pipe installations.

The fittings are made from PPSU (polyphenylsulfone) which is a high-performance polymer that has excellent impact and chemical resistance. It is commonly used in the fields of avionics due to its lightweight nature and flame-proof characteristics, and in medical applications such as human joint replacements due to its high impact strength and compatibility with human tissue. The material is also lead-free, making it the safest choice for drinking water applications.

Jointing

Patented tools flare the pipe around the fitting to maintain precise inside diameters of the fittings, reducing pressure drops throughout the fittings. The pipe is then locked on the fitting by a tight collar/cap connection and can be unlocked and used again.